Catalyst App

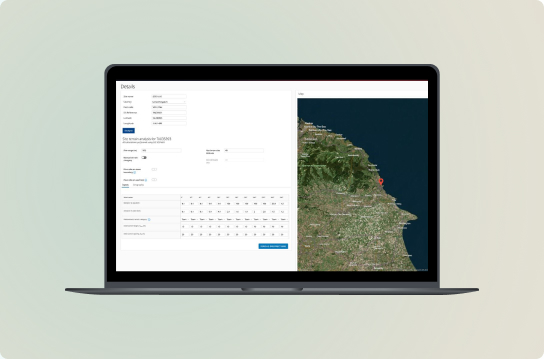

It is an innovative design software that simplifies the process of creating and specifying cold-rolled secondary steel elements. The integrated wind design engine utilizes advanced terrain and topography data from CORINE Land Cover and EU-DEM Layers, ensuring accurate site analysis for modern projects.

Explore Case study